I’ll update this whilst I’m on.

I almost have the rear beam ready for painting, it’s really difficult to get that rubberised coating off, which I suppose is really a good thing. I did consider just getting any loose stuff off, but what the hell, May as well do a decent job of it.

I have far too much stuff lying about. Stripped the spare seat base down, needed the little gearboxes for the passenger frame, I’d had to break them off to get the passenger seat out, something had been jammed into them.

Easy enough to swap over.

Given the corroded state of the seatbelt tensioner, I suspect that may be one of the reasons for the warning lights. I’ll source a spare.

I acquired a pair of wide sill covers quite a while ago, one was ok, one had been lined with fibreglass csm. They’re not structural, it seemed a decent job, so I wasn’t at all bothered. Then I dropped them, whilst trying to put them into the ladder bracket in the roof of the garage and store them out of the way. The good one bent a flange, easy fix. The repaired one hit the edge of my welding bench which punched a hole in it.

Didn’t take much of a look and I could see the ‘glass was now loose. A quick pull and . . . Oh Dear.

With bells on. Didn’t take much of a wire brush to reveal pinholes. Those will become gaping holes by the time rust is ground back. I’m pretty sure there won’t be enough metal left to ‘glass over. It’s not the curved/flared areas, those are solid. The temptation to see if I can weld the rear to my current narrow sill is strong. Or, just fold a panel up and butt weld it on, the flanged edge would be the first job for my newly motorised bead roller. Easy, if tedious, to avoid distorting it. I really need a quieter compressor to zap and chill that length of weld though, may be a weekday job when all the neighbours are at work. 1mm steel, fairly easy to bend that up, what the hell, I’ll whip the passenger sill off, see how far away it is, and if it won’t fit, I’ll bend up a repair section. Well two sections really, I only have 1M lengths of sheet steel and 1.5M box section to bend it over.

Ooh, and we’re experiencing a power cut here, a taste of things to come maybe.

Started a cull of all the surplus parts and wheels, with my son now home the garage is nearly impossible to get into.

But wait, there’s more, I completely forgot.

I had the front end Several Feet in the air, not to keep all the neighbours thinking “What the Actual **** is he doing now!” But to find out if you can fit an Eaton M62 ( a supercharger), in place of the air con compressor I don’t have, don’t want and don’t need.

The answer is; yes you can, but only if you want a supercharger shaped ornament as there is no space for the manifolds. I could reverse mount it, but the bracket would be monstrous. And I’d need a new radiator. Getting pipe work to and from an intercooler wouldn’t be much fun in that orientation either. No pics, I couldn’t hold the Eaton and take pics at the same time, not without risking a supercharger shaped dent in my face.

So I’ve sold it, but the desire to buy a physically smaller Aisin AMR500 supercharger is hard to resist. Very hard, because that will fit the space easily.

And yes, I do know there are kits for fitting both to the M44, but I don’t like them.

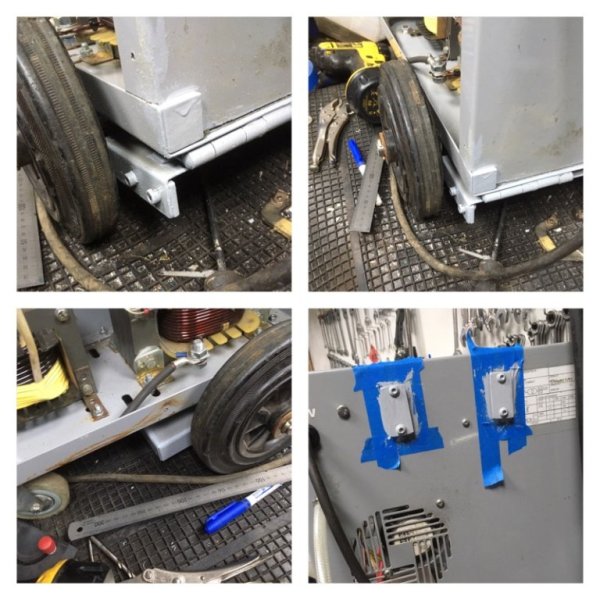

Lifting the car up, as I’ve been doing, well, a lot recently, is annoying. Really annoying. As I’m going to have the sills off, I’m thinking sill stands. Simpler, and a lot safer, than axle stands. And if I make a set, rather than buying them, I/we could use them for my sons E36 Touring when required. That would mean interchangeable pins. Younger lad is helping me design something in Fusion 360. We’re thinking twin height, that would mean a low height for wheel changes/brakes, higher setting for full underneath access.

I will need to come up with some sort of plug, or bung, for the outer sills to keep it all neat. I expect that may be the most time consuming part requiring several iterations, the rest is just welding.

I almost have the rear beam ready for painting, it’s really difficult to get that rubberised coating off, which I suppose is really a good thing. I did consider just getting any loose stuff off, but what the hell, May as well do a decent job of it.

I have far too much stuff lying about. Stripped the spare seat base down, needed the little gearboxes for the passenger frame, I’d had to break them off to get the passenger seat out, something had been jammed into them.

Easy enough to swap over.

Given the corroded state of the seatbelt tensioner, I suspect that may be one of the reasons for the warning lights. I’ll source a spare.

I acquired a pair of wide sill covers quite a while ago, one was ok, one had been lined with fibreglass csm. They’re not structural, it seemed a decent job, so I wasn’t at all bothered. Then I dropped them, whilst trying to put them into the ladder bracket in the roof of the garage and store them out of the way. The good one bent a flange, easy fix. The repaired one hit the edge of my welding bench which punched a hole in it.

Didn’t take much of a look and I could see the ‘glass was now loose. A quick pull and . . . Oh Dear.

With bells on. Didn’t take much of a wire brush to reveal pinholes. Those will become gaping holes by the time rust is ground back. I’m pretty sure there won’t be enough metal left to ‘glass over. It’s not the curved/flared areas, those are solid. The temptation to see if I can weld the rear to my current narrow sill is strong. Or, just fold a panel up and butt weld it on, the flanged edge would be the first job for my newly motorised bead roller. Easy, if tedious, to avoid distorting it. I really need a quieter compressor to zap and chill that length of weld though, may be a weekday job when all the neighbours are at work. 1mm steel, fairly easy to bend that up, what the hell, I’ll whip the passenger sill off, see how far away it is, and if it won’t fit, I’ll bend up a repair section. Well two sections really, I only have 1M lengths of sheet steel and 1.5M box section to bend it over.

Ooh, and we’re experiencing a power cut here, a taste of things to come maybe.

Started a cull of all the surplus parts and wheels, with my son now home the garage is nearly impossible to get into.

But wait, there’s more, I completely forgot.

I had the front end Several Feet in the air, not to keep all the neighbours thinking “What the Actual **** is he doing now!” But to find out if you can fit an Eaton M62 ( a supercharger), in place of the air con compressor I don’t have, don’t want and don’t need.

The answer is; yes you can, but only if you want a supercharger shaped ornament as there is no space for the manifolds. I could reverse mount it, but the bracket would be monstrous. And I’d need a new radiator. Getting pipe work to and from an intercooler wouldn’t be much fun in that orientation either. No pics, I couldn’t hold the Eaton and take pics at the same time, not without risking a supercharger shaped dent in my face.

So I’ve sold it, but the desire to buy a physically smaller Aisin AMR500 supercharger is hard to resist. Very hard, because that will fit the space easily.

And yes, I do know there are kits for fitting both to the M44, but I don’t like them.

Lifting the car up, as I’ve been doing, well, a lot recently, is annoying. Really annoying. As I’m going to have the sills off, I’m thinking sill stands. Simpler, and a lot safer, than axle stands. And if I make a set, rather than buying them, I/we could use them for my sons E36 Touring when required. That would mean interchangeable pins. Younger lad is helping me design something in Fusion 360. We’re thinking twin height, that would mean a low height for wheel changes/brakes, higher setting for full underneath access.

I will need to come up with some sort of plug, or bung, for the outer sills to keep it all neat. I expect that may be the most time consuming part requiring several iterations, the rest is just welding.

Last edited: