(This might be best read on my blog - I've reposted all the content here but having trouble adding in-line images so they're all at the bottom. You can find it here: https://projects.tomcheesewright.com/2021/06/06/monster-update/)

You know how it is with big projects: life gets in the way. So I won’t bore you with the details. But, things are flying again on the Z300 EV project. In bullets first just give me an agenda for my own post:

- All the welding on the rear quarters is done

- All the remaining mounts and brackets are finished

- The motor cooling loop is in

- The inverter/charger cooling loop is largely done

- I’ve started wiring up both HV and 12V again

This is why I called this a monster update! (Though I said the same about the last one).

To break things down in a bit more detail:

Rear Quarters

If you have been following this project, you will know that I bought an absolute lemon that required a lot more welding than I planned for. Anyway, that is all now done. Is it pretty? No. Do I think it will get through an MOT? Yes.

The main problem areas were the top mounts for the rear springs, and the strut top for the offside rear. I welded that up a while back and wasn’t very happy with it at the time. But when I came back to it with a bit of distance I decided that though it was far from pretty, it was actually very solid.

The spring mounts required some serious fabrication though. Two parts had largely dissolved. The mount itself, a disc of metal with a round locating nub in the middle. And the cover/brace piece that sits between the disc and the upright section of the car body. You can probably make better sense of this from the photos.

I couldn’t find repair panels for these parts so I decided to half repair, half make my own. I cut some 130mm discs out of 3mm steel, and then drilled large holes in the centre so that the locating nubs – which hadn’t rusted – would protrude through. This means there is less ‘nub’ than there would have been originally, but having tested it with a spring, they still seem to locate fine. The springs will sit a couple of millimetres lower as a result – and perhaps the car a little higher – but I don’t think anyone is going to notice.

My neighbour asked if I was going to get these laser cut. “Um, no, I’m doing it with an angle grinder.” Next time, I will get them made by someone who can draw a circle.

I couldn’t get the discs to locate perfectly flat against the car tub, so had to put some chunky welds in, in places. But I think the weight should be fairly well distributed. And they seem to be at the same angle as what was left of the original parts. I may have some issue when it comes to reinstall the rear suspension assembly, but we shall see.

For the cover/brace, I used the classic CAD (cardboard aided design) approach and then cut and folded some steel to match the pattern. Can’t remember the thickness off the top of my head (I’m writing this after a couple of beers) but they are very stiff. Maybe 1mm? I partially seam welded these in so they add a lot of rigidity.

The whole lot was then coated in red oxide primer, then paint, then seam sealer, then a coat of stone chip for good measure. If I’ve done it wrong, it will be easier to scrap the car than get all that crap off. And TBH, if this fails its MOT on structural issues, that is what I will do. The car owes me maybe £300 and I can get that back by selling off parts. So I will just treat this as a training exercise/development mule, strip out the bits I’ve added and move them to a more solid donor.

Mounts and Brackets

In the last update I said I needed to redo the mounting brackets for the inverter and charger. I didn’t mention that I still needed to make mounts for:

- The oil pump (for motor cooling)

- The oil reservoir

- The oil cooler

- The water pump (for inverter and charger cooling)

- The radiator/reservoir

Starting with the big parts, I went and bought some new 20mm box section with fairly thick walls (1.5mm again I think) and started fabbing up some new mounts to sit across the top of the engine bay, close to the firewall. The inverter sits in front of the driver and the charger on the passenger side. With a bit of fettling, these now sit nicely lined up and leave plenty of room to get into the battery box. They also leave room for all the cooling bits.

I made up a bracket to hold the oil cooler down to the left of the motor on the engine bay image. It’s horizontal, which is a bit weird. And the clearance to the cross member isn’t amazing. But it doesn’t seem to touch it under pressure. And it means it can act as a giant U bend, taking the warm oil out of the motor and feeding it back into the reservoir. For this, I have re-used the old ATF reservoir from the old power steering system.

The reservoir and the oil pump are mounted on a plate to the right of the motor on the picture below. This is welded to the frame that carries the charger, and bolted to the transmission adaptor plate as well. I should cut away the excess on the plate but I decided to leave it for now in case anything else needed mounting there.

From the pump, the oil goes through a right angle bend then up and over and into the top of the motor. Don’t have any pics of this pipe yet.

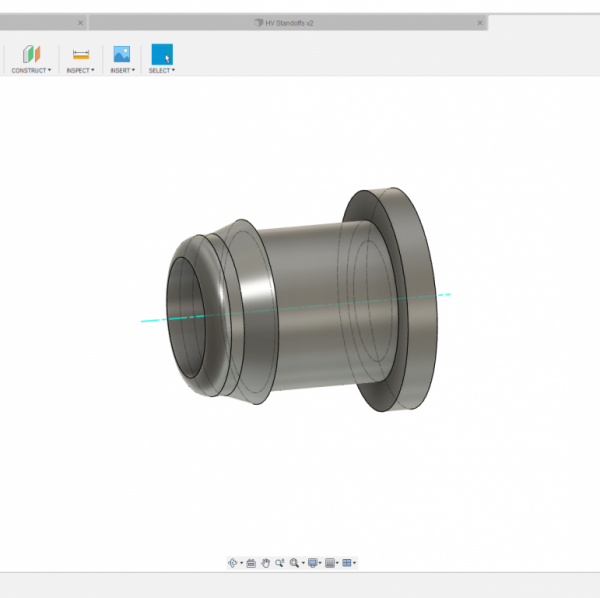

That pretty much completes the oil cooling loop. I just need to make a plug to block off the secondary outlet on the bottom of the motor. I’m going to 3D print this from PETG. It’s fairly chemical resistant and I don’t foresee the motor temperature getting very high. If it does, I’ll get one machined out of brass or something.

The water pump is now mounted off the side of the charger on another bracket I made up. Could do with a bit of a trim and the paint isn’t great but I’m focused on function for now.

The pump runs water through the charger, then into the inverter via a bit of a dogleg using another 3D printed part. Designing tubes for printing is a ballache, especially if you are trying to avoid using support materials. Hence the funny shape.

From the inverter, the coolant runs down to the little motorbike radiator, now mounted in front of the battery box. Lots of air flow and well out of the way. These brackets are welded to the old front valance (and yes, I will give the whole thing a coat of paint eventually).

Cooling loops

With all the components in place, adding the cooling loops is ‘simply’ a matter of running the right sized hoses, elbow pieces, and lots of jubilee clamps. These are proving to be another ballache, especially in tight spaces. I think the jumbo pack of jubilee clamps I got from a discount supermarket about ten years ago maybe aren’t great quality. Who knew?

Anyway, most of the hoses are now in apart from the last links to the radiator, and the dogleg between inverter and charger (I snapped the first 3D printed part so currently reprinting with thicker walls). I’m looking forward to testing these, not least because no-one has mapped the resistance on the thermistor in the motor I’m using yet, so I won’t be able to get accurate temperature readouts until I do.

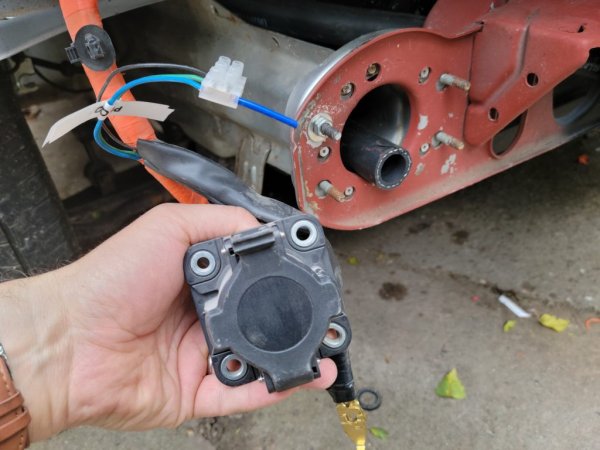

HV Wiring

Finally on this monster update, wiring. The HV wiring is largely done, with the exception of the heater. I still need to find space for a box to carry an Arduino, or similar, and contactor, to provide me with sensing and switching for the water heater and pump. And I haven’t yet made up a part to integrate the temperature sensor into the heating loop, though I now have an idea for how to do this.

The last wires I had to make up on the HV side were to carry DC from the inverter auxiliary connection to the charger. Using the same 35mm2 cable for this and it’s just two short runs. I still need to make up some shrouds for the ends of these to keep the inverter and charger better sealed from moisture. Tried a couple of designs so far but nothing I’m happy with. Don’t really want to just dump a load of silicone in there.

I have decided to mount the charging port in the front bumper for now, in one of the blanked off fog light spaces. It’ll get a little mucky but it’s not like it’s going to be there for long, or like I’m going to be travelling long distances on 8kwh. It just means I don’t need to extend any of the cables. When I do the rebody, I’ll put it somewhere proper.

12V Wiring

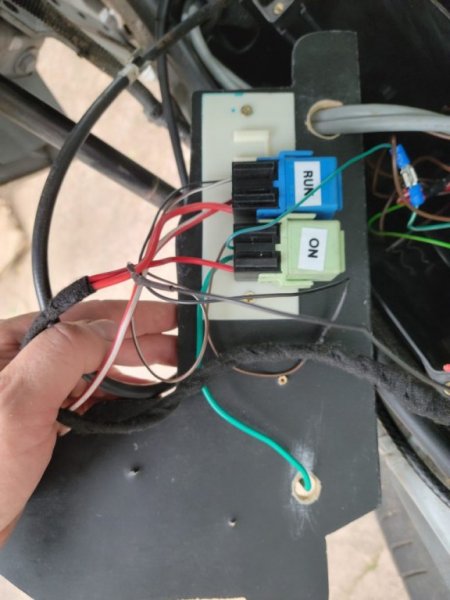

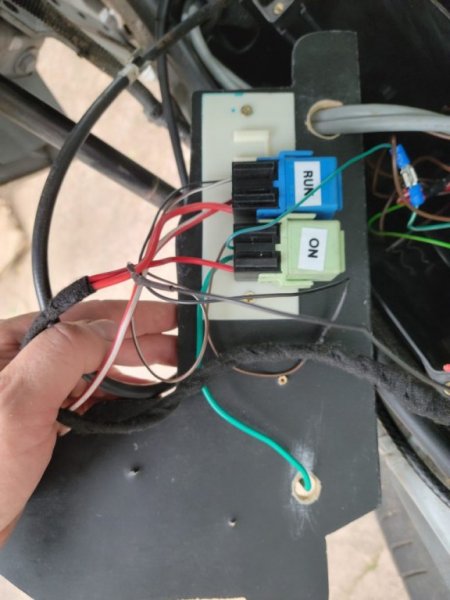

Absolutely last for this update is the 12V wiring. This is time consuming. And right now, a mess. I’m having to strip back some of the loom I thought was pretty finished in order to get the charger connections in neatly, and also because I have come to the conclusion the stubs on my CAN bus wiring were too long. Very grateful for my gas soldering iron right now, so I can cut and join things in situ.

I’ve done a couple of things to try and make it all a bit neater. First, I’ve ditched the plastic insides of the sealed ECU box on the driver’s side of the engine bay and replaced them with a flat MDF shelf. This will allow me to lay out my fuse boxes and relays nice and neatly, and hide away any unused wires from the original loom. I stupidly painted this before making all the final holes so I will have to pull it out and repaint it at some point.

The second thing I’ve done is start to re-introduce some of the original plastic and rubber wire management pieces, including the shelf/conduit that bolts in along firewall. This needed some trimming in order to fit, but it should keep things nice and tidy.

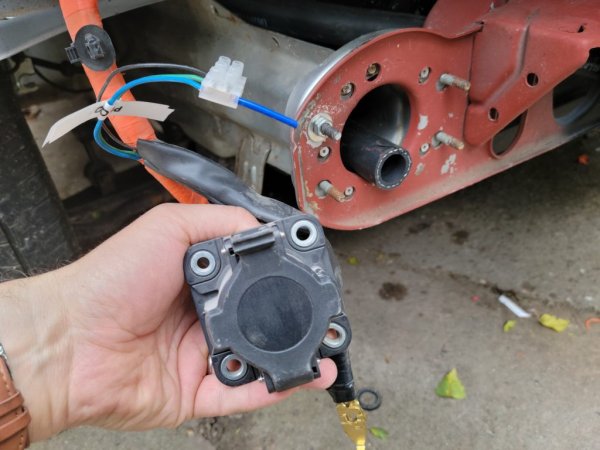

I don’t want to start wrapping anything just yet until I know it all works. And the AMPSeal connector on my inverter is a total mess, as are the connections to the motor for temperature and position. Lots of work still to do here.

Progress

Nonetheless, it feels like the project has taken massive steps in the last week and I’m really pleased.

Next steps are to finish reassembling the back end. I can’t find the anti-roll bar mounts at the moment (they must be somewhere – I know I painted them) and I’m waiting for replacement strut tops as I managed to throw one away. I still need to redo the two sets of flexi brake lines on the back end, as well as the hard lines that mount on the back axle assembly. First attempt at bending and flaring brake pipes so that will be fun. And I haven’t yet used the brake caliper rebuild kits I bought maybe six months ago, though the rusty old calipers are now looking shiny in a coat of paint.

At the front end, I still need to get a high pressure line made up to connect up the PAS pump, and putting that in will require taking everything else out. When I do that, I’ll give some of the brackets a coat of paint and maybe tidy up the engine bay a bit. Really pleased with the Hycote stone ship paint I picked up at the local motor factors so might get some more of that and do the sills as well.

There’s the plumbing to finish and test. And the wiring. So much wiring.

Then it’s the scary bit: getting the laptop out and trying to make it all work again. Thinking I might add an Arduino Mega into the CAN bus loop and run a USB cable into the cabin to make testing easier.

But as Ed China says, that’s a job for another day.